1955 - Birth of engines

First appearance of UD’s logo - symbol of a high-performing engine.

Completion of the first diesel engine and first diesel truck

Nihon Diesel Industries, Ltd. (currently UD Trucks Corporation) opened its doors in Tokyo in December 1935. Early on, the company brought in technologies from Europe and constructed a new plant in pursuit of its goal to create the first diesel engine. Both the factory and the processing technology lacked sophistication, which made even the simple production of parts that satisfied the required levels of precision and quality a daunting challenge.

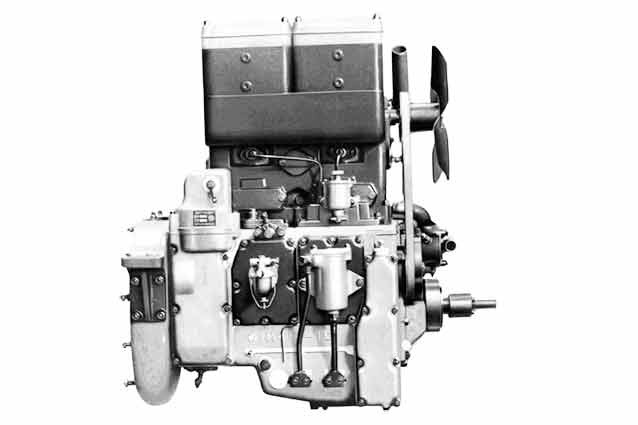

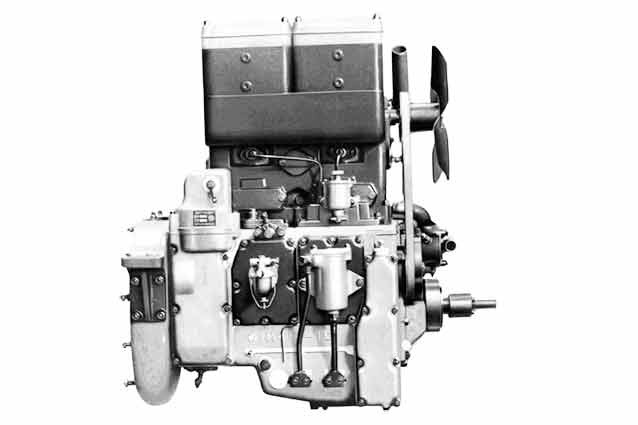

Beyond that, the company was struggling to get the required funding to stay afloat. Kenzo Adachi, the founder of Nihon Diesel Industries and his team took on a never-give-up attitude. Their commitment and passion finally paid off in November 1938, close to three years after the company was founded, with the completion of the first diesel engine: the ND1.

The ND1 was an opposed-piston uniflow engine with a revolutionary design featuring no cylinder heads or air release valves.

A year later in November 1939, a 2.5-ton payload diesel truck equipped with an ND1 engine, known as the LD1 truck, was completed. Four years after the foundation of the company, Kenzo Adachi’s dream to build a diesel vehicle in his own right had finally been realized and immediately decided to put the new machine to the test with a 3,000km expedition on Japan’s toughest roads. Galvanized by this first technical success, put through its paces in real life conditions, Nihon Diesel Industries set about expanding and enhancing the ND engine series by gradually increasing the number of cylinders. The development of the three-cylinder ND2 engine (90 horsepower) was completed in the same year.

The 2.5-ton payload LD1 completed in November 1939 was the first diesel truck

produced by Adachi and his team (The photo is LD3 truck)

Upon entering the 1950s, Japan had emerged from a period of recovery and in preparation for new economic growth was busy constructing infrastructure that included power sources, roads, railways, ports and large-scale plants. A deficiency in transportation capacity came under close scrutiny, however, due to its importance in driving infrastructure development. As a result, demand for large, high-horsepower trucks rose.

At the time, no Japanese company made large trucks with engines in the 200-horsepower class required for the long-distance transportation industry. In light of this need, the company sought to develop its own large diesel engine in 1953. Two-cycle engines in those days were noisy and the height was high. This prompted the introduction of uniflow scavenging, in which air enters at the lower end of the engine cylinder and exits through an outlet at the top, thereby enabling an improvement in scavenging efficiency as well as low noise and light weight, while maximizing the high power of the two-cycle engine.

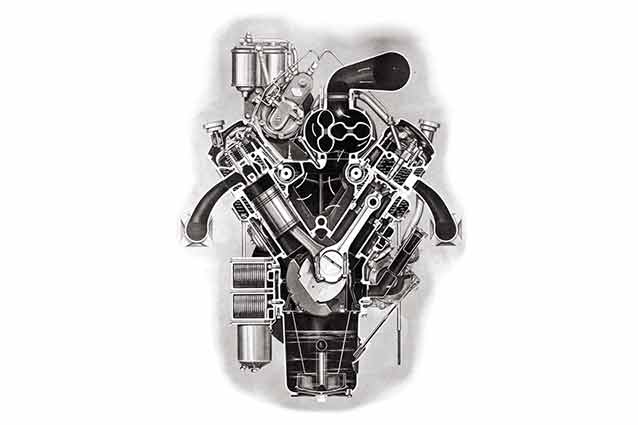

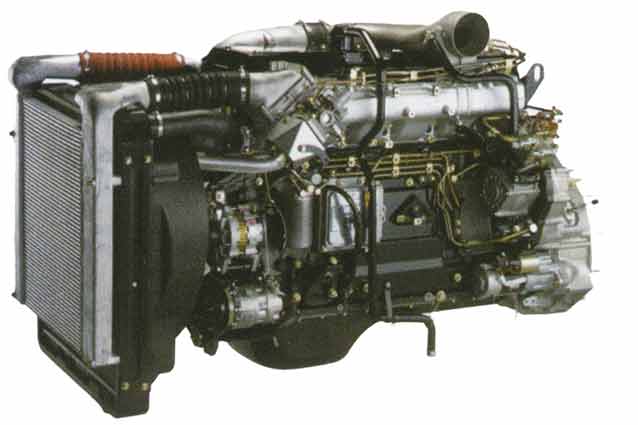

In January 1955, the company released two new diesel UD engines: the three-cylinder 110-horsepower UD3 and the four-cylinder 150-horsepower UD4. The six-cylinder 230-horsepower UD6 was subsequently launched in June. Of particular note, it was 40% lighter than the company’s conventional engines in terms of weight per horsepower, making this highly acclaimed engine one of the world’s lightest per horsepower. The brand status of UD engines was immediately enhanced.

The UD engine, a newly designed diesel engine, was released in January 1955. While maximizing the high power of a two-cycle engine, the UD engine employs uniflow scavenging to bolster scavenging efficiency and at the same time minimize noise and enable compact, lightweight design.

UD internationally recognized trademark

“UD” originally stands for the abbreviation of uniflow scavenging diesel engine. Since a variety of different engines were being developed at the time, the company decided to stamp the UD mark on its design drawings to differentiate it from the competition. Thereafter, in order to appeal the high engine performance of trucks equipped with a UD engine, the UD mark was put on the body of the vehicle. This mark became the international trademark for our company and led to its current name.

UD engines : an evolution of fuel efficiency innovation

Since its inception until the present time, fuel efficiency innovation has always been central to UD Trucks’ competitiveness

From the company’s first Japan-made engine produced in late 1938—the milestone 60 horsepower ND1 – the focus on delivering fuel efficiency innovation remains a competitive hallmark.

Durability, reliability and efficiency are at the heart of every UD engine. These keywords, which today are central to the UD Trucks DNA, have continued to drive the company’s success. In early 1955 came the iconic two-stroke UD engine. The race for horsepower had begun, and in Japan and overseas, trucks were traveling farther and bus passengers wanted to go faster. Engines capable of 150–200 horsepower were in huge demand. The Uniflow scavenging Diesel engine—the origin of the UD name—was the first produced by a Japanese company to reach this level. The industry-first 150 horsepower version was followed by the UD6 engine, which further delivered 230 horsepower at a weight 40% lower than conventional models, making it one of the world’s lightest per horsepower. For truck owners, this meant lower vehicle weight and in turn less fuel used for a given distance and payload.

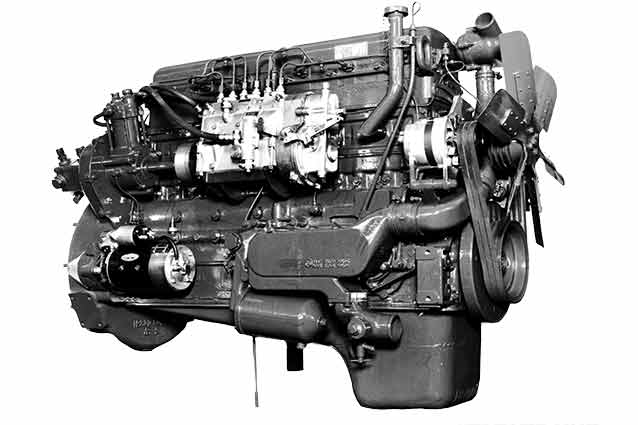

At this time, engine power rather than fuel efficiency guided innovation, resulting in the turbocharged engine in 1971, a Japan first, and two world firsts, the continuously controlled variable nozzle turbocharger engine in 1990, and the ceramic tappets for a 4-valve medium-duty engine in 1993. With ever-stricter environmental regulations in the latter half of the 1990s, fuel efficiency became a key sales driver of UD Trucks. Founder Kenzo Adachi’s spirit continued to lead the way, spurring innovation focused on combining efficient engines with multi-speed transmissions to deliver the best possible torque at all times.

The ESCOT-II, Japan’s first electronically controlled semi-automatic multi-speed transmission for heavy-duty trucks, made its debut in 1995. The GE13 engine produced in 1998 was the first in the world to include a ball-bearing turbocharger for better mechanical efficiency, stronger throttle response and less oil needed for lubrication. Together, these engines delivered superb mileage and solidified the company’s reputation for excellent fuel efficiency.

In 2004, complying ahead of schedule with Japan’s 2005 emissions regulations—world’s strictest at the time—Quon set a global benchmark for fuel efficiency and environmental performance. Built from the ground up for lower fuel consumption, the heavy-duty truck touted an aerodynamic cab and body parts, a lightweight chassis, a new type of ultra-high-pressure fuel injection that drastically improved fuel combustion and the world-first urea SCR technology for breaking down NOx and CO2 in the exhaust. Such technologies were successively applied to the latest GH11 engines and its series, as well as Quon and Condor in which those engines are mounted. With its eco-mode and ESCOT-Roll functions, the ESCOT-V electronically controlled automatic transmission, in tandem with these technologies, provide our customers with superb fuel efficiency.

Launched In 2013, Quester, developed for global growth markets, featured built-in fuel efficiency and a specifically developed powertrain at its heart. This ensured that the heavy-duty truck’s 8-literand 11-liter engines operate within their peak efficiency power band at all times while giving customers the flexibility to select the powertrain combination that best suits their needs. Other components, including the 6-, 9- and 12-speed gearbox and added oil-cooler, are calculated to cut fuel costs without compromising on performance and durability.

The 2017 All New Quon is moved by a more fuel-efficient, greener, and torque version of the GH11 engine, which can be mated to the new electronically controlled ESCOT-VI gearbox. Adding to the qualities of the renowned ESCOT-V this new gearbox adds other fuel-saving functions, such as Foretrack. This system uses GPS to recognize a road already driven, and to predict what’s coming; Foretrack always choose the most adapted gear ratio according to the coming incline, decline or corner in cruise control driving mode.

The new Croner, fitted with the remarkable new GH5E and GH8E engines, also focuses on fuel saving. Exploiting the benefits of downsizing, the 4-cylinder 5-liter and 6-cylinder 8-liter engines provide the best fuel efficiency /payload ratio in the category. Fuel efficiency has definitely become a core quality of UD trucks, besides their legendary dependability.